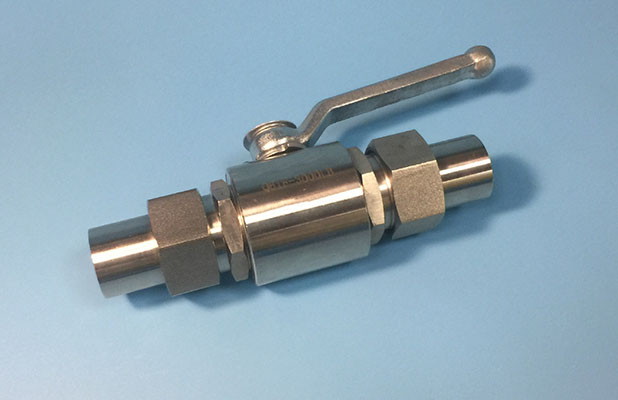

High temperature and high pressure plug-in ball valve

The ball valves sold by the company mainly have two structures: floating ball and fixed ball, and are divided into two sealing forms: soft and hard. There are four operating methods: manual, worm gear and worm gear transmission, electric, pneumatic, etc. These products are used in the management of corrosive and non corrosive media, as well as in oil and gas pipelines and the paper industry, and are satisfactory products for users. In recent years, many ball valve products with advanced structure, excellent manufacturing, and complete specifications have been developed to meet the needs of domestic and foreign users.

The ball valves of Canadian HT Valve Company are renowned worldwide for their absolute quality standards, reliability, and long service life under extremely harsh conditions such as high temperature, high pressure, high corrosion, and high impurities. The company's products have achieved or exceeded various international standards due to their excellent product quality, strict factory inspections, and acceptance quality standards. The various valves produced by Canadian HT Valve Company have officially entered the Chinese market, which will inevitably bring unexpected usage effects to Chinese users. The product quality exceeds your expectations, and choosing HT valves is your wise choice.

In the field of electricity:

With the continuous construction and operation of large power plant units, the operating parameters of the units are constantly improving, and the performance requirements for valves are also increasing. HT Valve is committed to solving the needs of harsh working conditions, producing metal hard sealed ball valves that truly achieve zero leakage standards, HT valves have been installed in 80% of power plants in North America. With its stronger sealing effect, longer service life, and simpler operation, it improves the safe and reliable operation of equipment, improves the efficiency of the unit, and reduces maintenance costs. Mainly targeting various steam pipeline drainage, exhaust, feedwater shut-off, discharge, switch type positions in power plants.

In the fields of petrochemicals and metallurgy:

For industries such as petrochemicals, metallurgy, papermaking, fire protection, etc. with high magazine content, high viscosity, and strong corrosion, HT valves utilize improvements in material selection and design processes, enabling them to effectively meet practical needs and achieve reliable operation in high-pressure oil and gas pipelines, as well as high-temperature pipelines in chemical and metallurgical industries, and corrosive media pipelines. Mainly targeting equipment such as catalytic cracking, reforming, and hydrogenation in refineries, refining equipment such as ethylene, coal powder gas shut-off valves in steel mills, and various slurry and slag removal systems. Meanwhile, HT valves can be specially designed and manufactured with special structures and materials (such as titanium alloy, Monel alloy, duplex stainless steel, etc.) according to various working conditions. Its excellent performance and lifespan always enable customers to achieve unimaginable results.