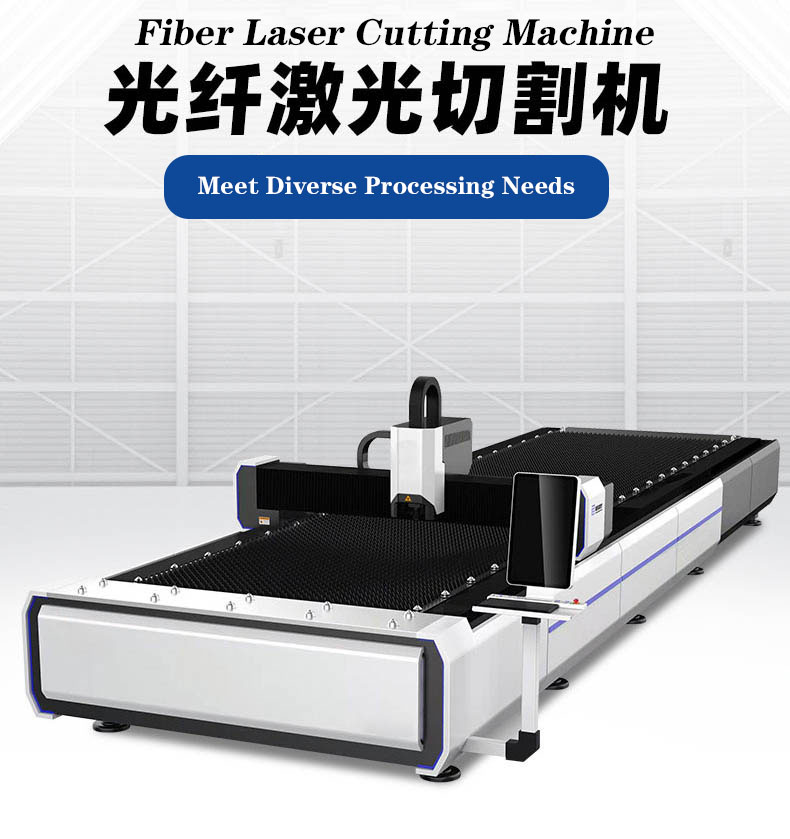

Introduction to Laser Cutting Machine Products

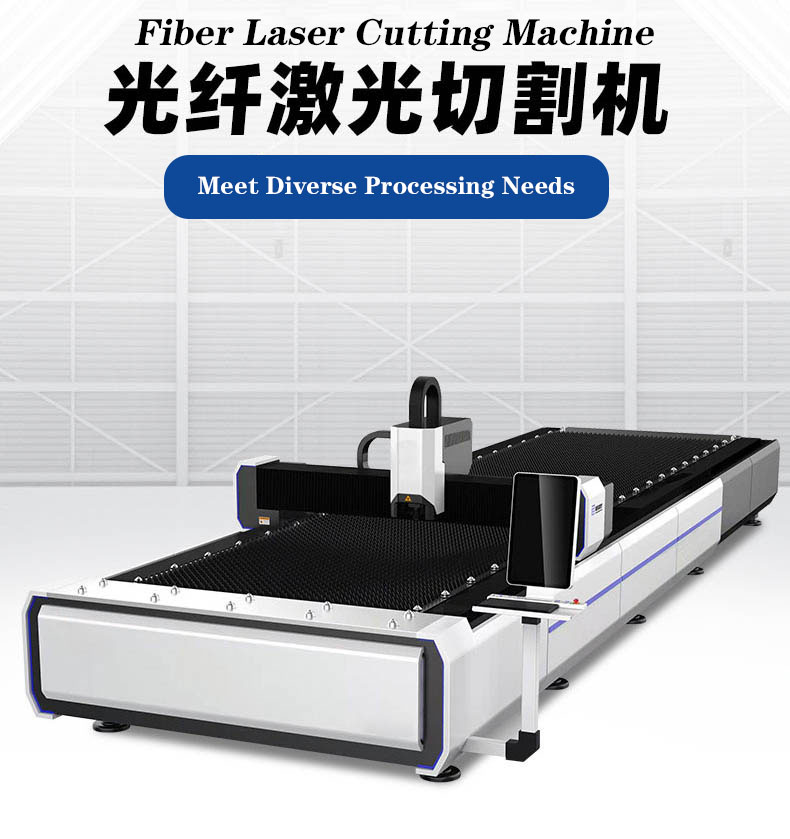

1、 Product Overview

Laser cutting machine is an indispensable and efficient cutting equipment in modern manufacturing industry. It adopts advanced laser technology and achieves fast and non-contact cutting by irradiating the surface of the workpiece with a high-energy laser beam. Laser cutting machines are widely used in the cutting and processing of various materials such as metals and non-metals, especially in the field of metal sheet cutting, and their advantages are particularly obvious.

2、 Technical characteristics

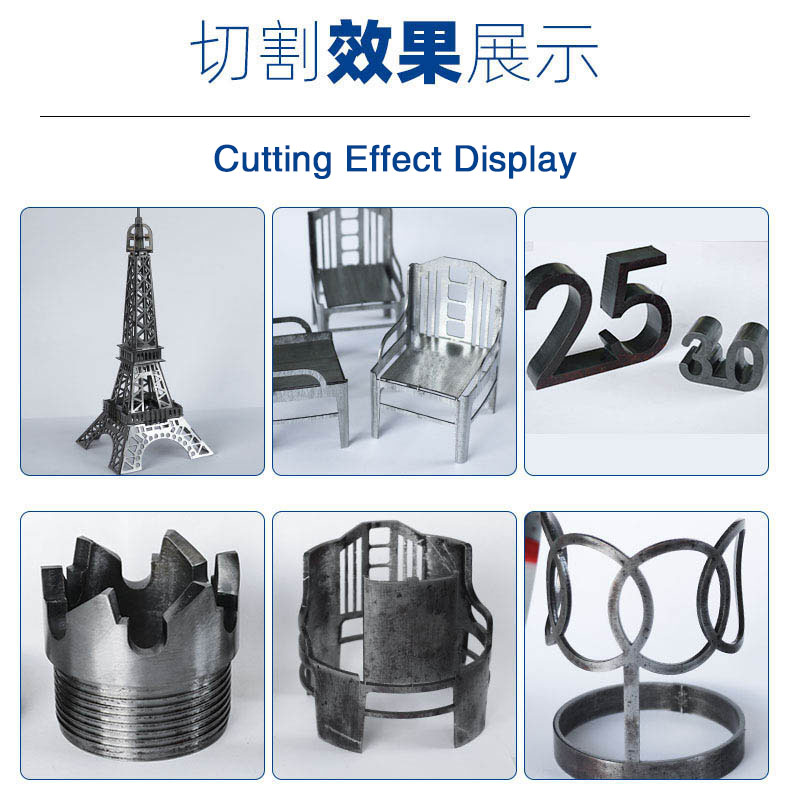

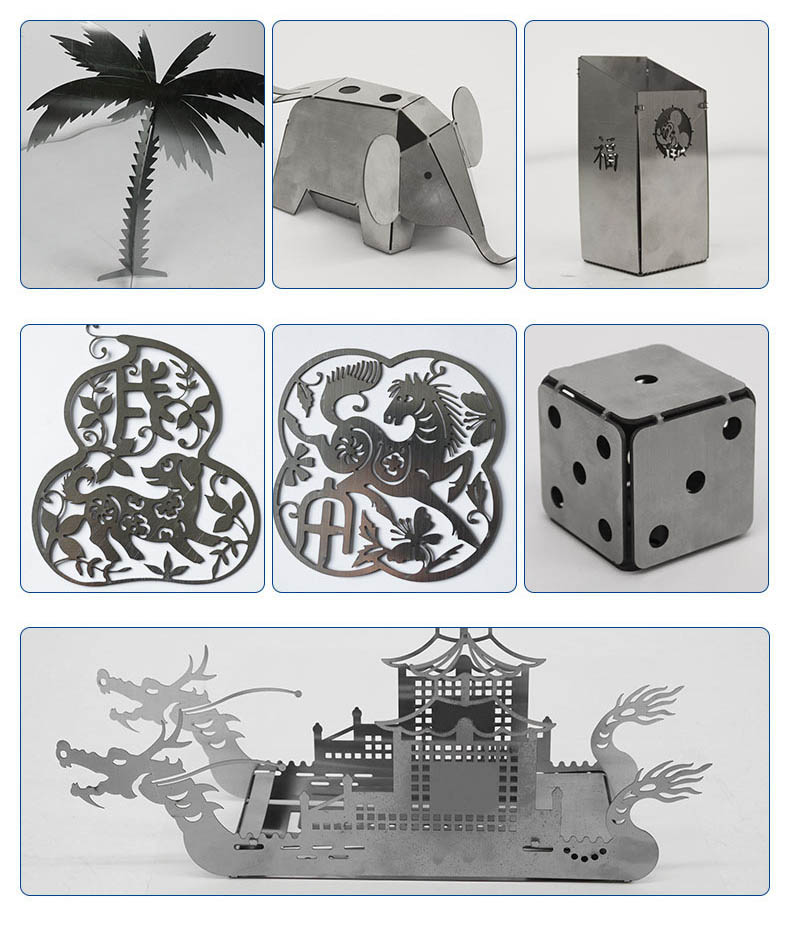

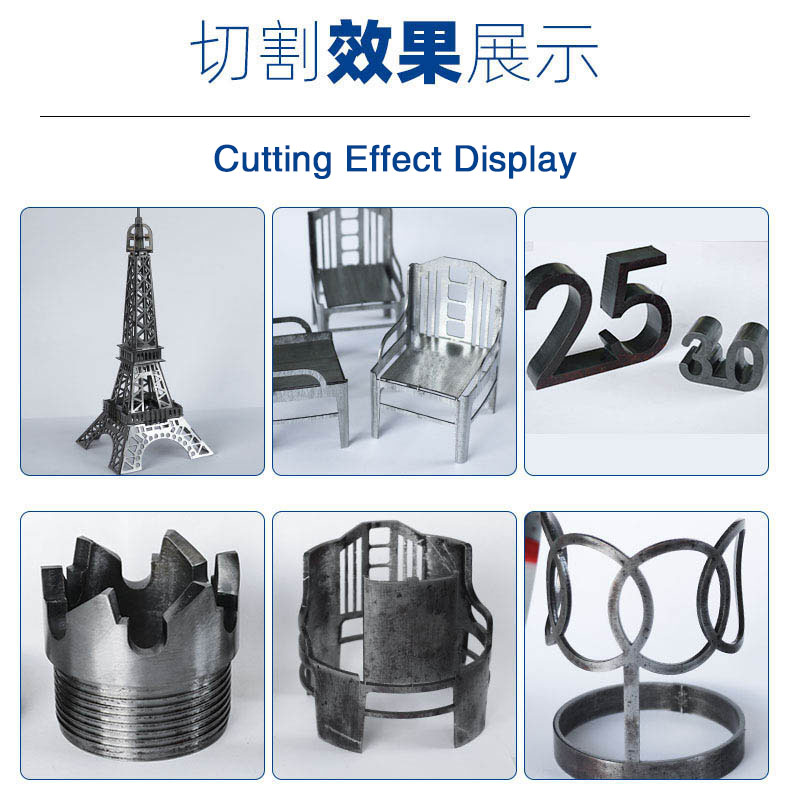

High precision cutting: Laser cutting machines have extremely high cutting accuracy, which can meet the precise cutting needs of various complex shapes, ensuring the flatness and smoothness of the cutting edges.

Efficient processing: Laser cutting has a fast speed and can complete a large number of cutting tasks for workpieces in a short period of time, improving production efficiency.

Small heat affected area: During laser cutting, the energy of the laser beam is highly concentrated, the heat affected area is small, and the thermal damage to the workpiece material is small, maintaining the original performance of the material.

Non contact machining: Laser cutting is a non-contact machining method that avoids mechanical stress and material deformation, making it particularly suitable for precision machining.

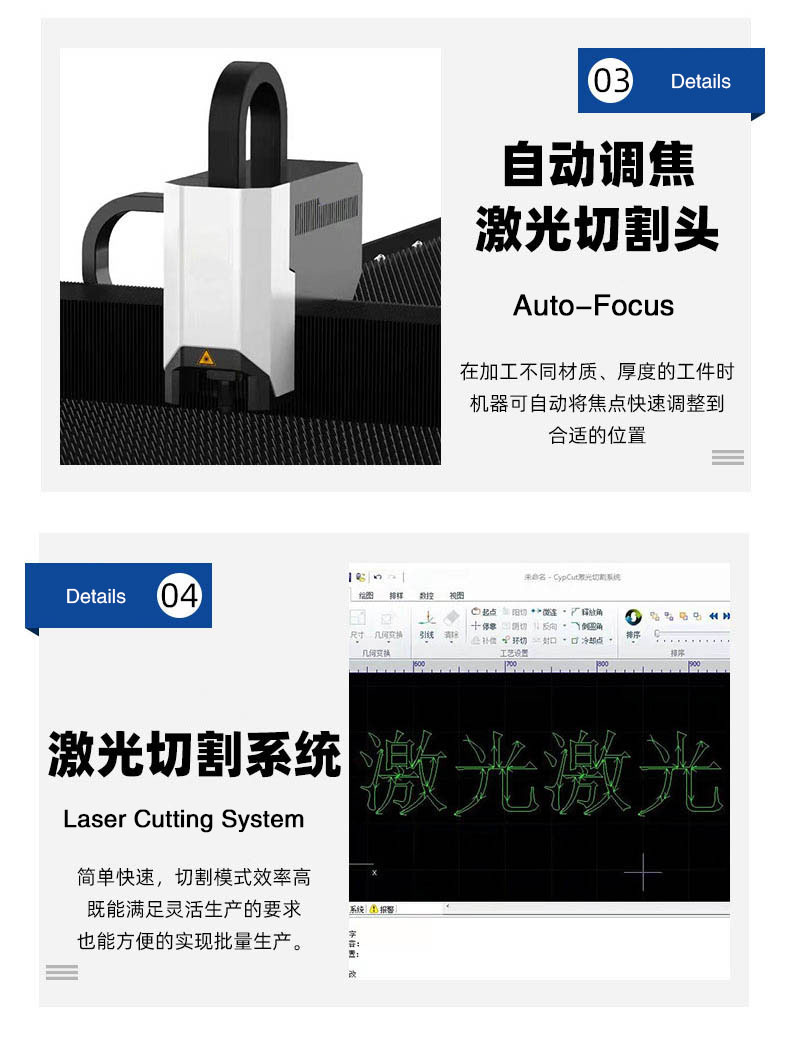

Strong adaptability: the laser cutting machine is suitable for cutting various materials, including metal, non-metal, plastic, etc., and has different cutting strategies for different materials and thicknesses.

3、 Product advantages

Efficient and energy-saving: The laser cutting machine adopts advanced laser technology and control system, which can achieve efficient and energy-saving cutting processing.

Easy to operate: The device is equipped with a user-friendly interface, making it easy to learn and reduce the difficulty of operation.

Safe and stable: The equipment is designed reasonably and adopts multiple safety protection measures to ensure safety and stability during use.

Easy maintenance: The equipment has a compact structure and is easy to maintain, reducing maintenance costs.

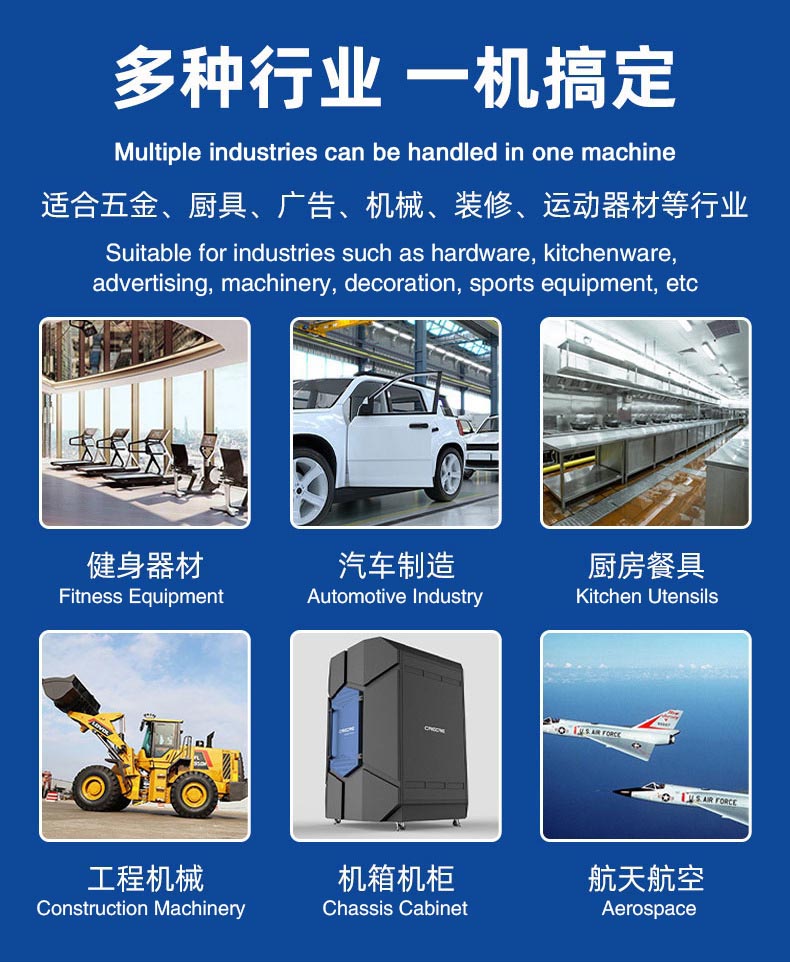

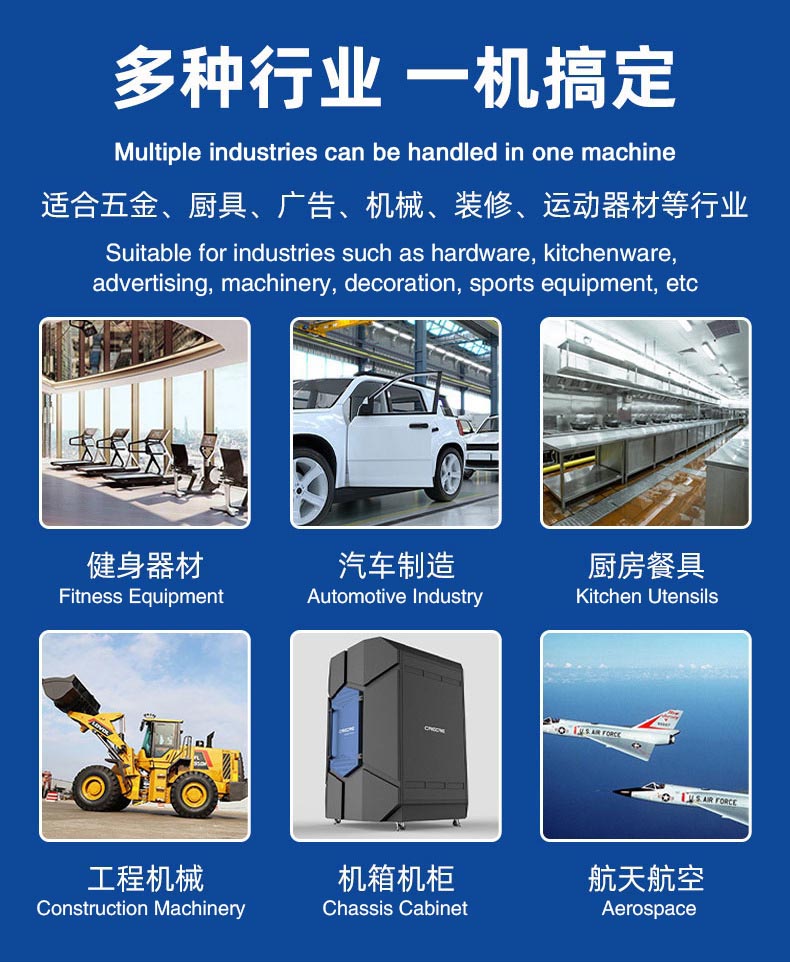

4、 Application field

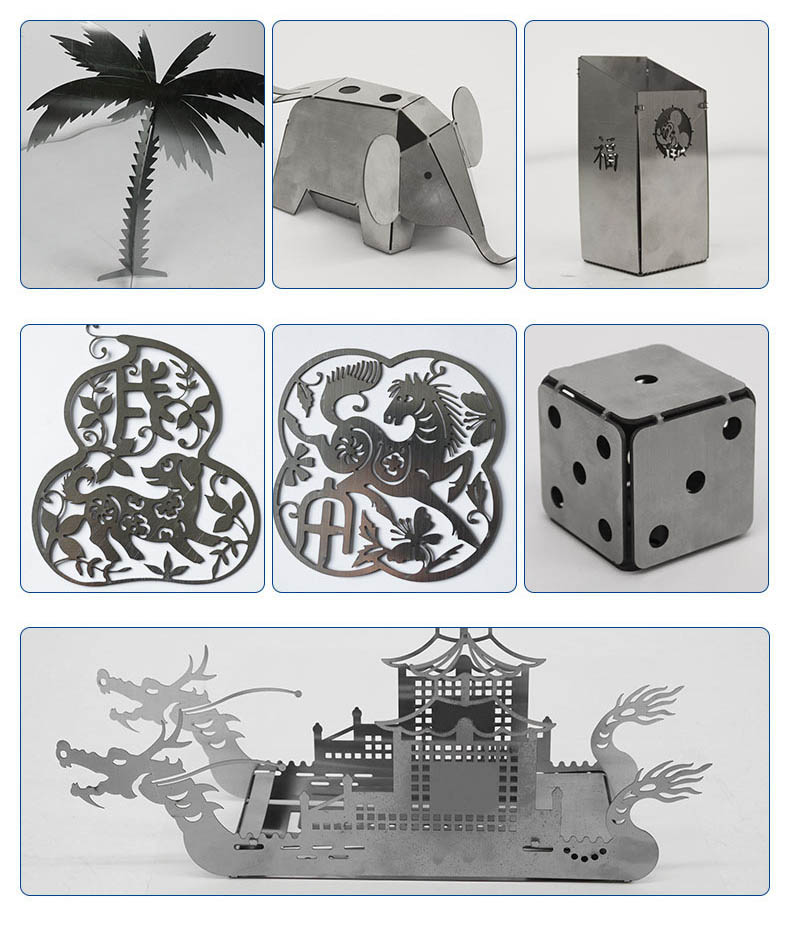

Metal sheet cutting: Laser cutting machines are widely used in the cutting and processing of metal sheets, such as stainless steel, carbon steel, alloy steel, etc.

Non metallic cutting: The cutting and processing of non-metallic materials such as plastics, rubber, wood, etc., to meet the cutting needs of various complex shapes.

Precision machining: suitable for precision machining of precision mechanical parts, electronic components, and other fields.

5、 Usage

Preparation for startup: Check if all components of the equipment are intact, connect the power supply, and turn on the power switch of the equipment.

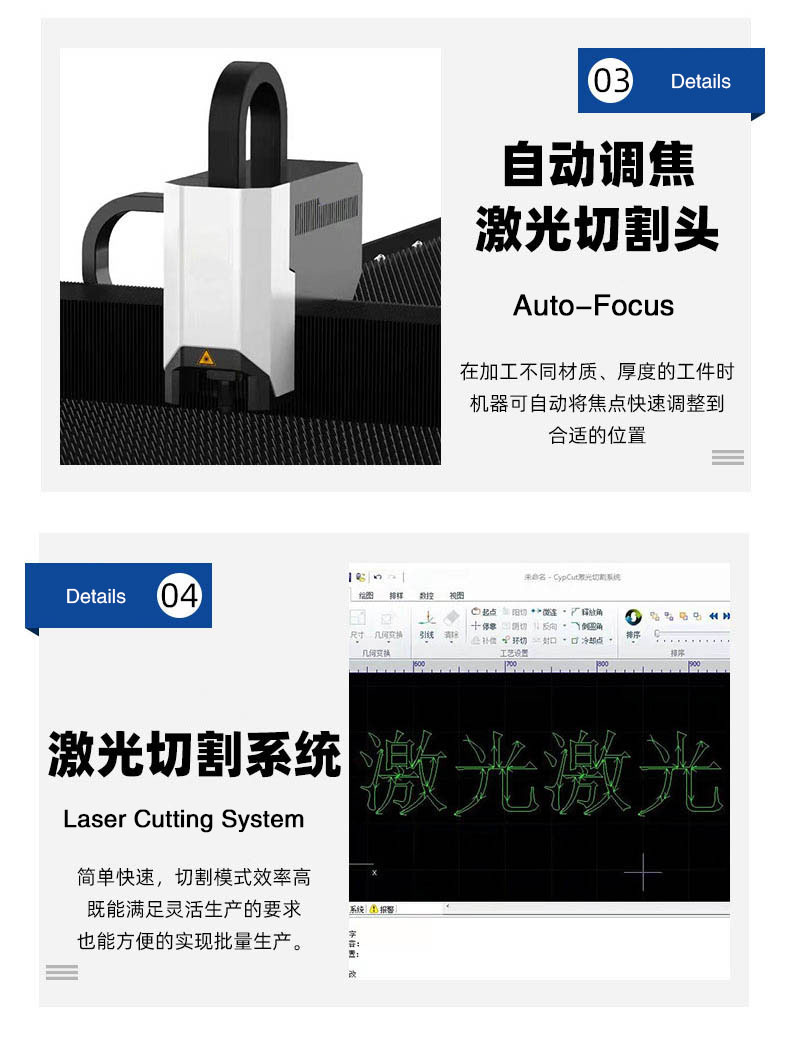

Import graphics: Import the graphics file that needs to be cut into the control system of the device.

Set parameters: Set appropriate laser power, cutting speed, and other parameters based on the material and thickness of the workpiece.

Start cutting: Place the workpiece on the equipment workbench, start the cutting program, and the equipment will automatically perform cutting processing.

End cutting: After cutting is completed, turn off the power switch of the equipment and clean up any residues inside and outside the equipment.

6、 Maintenance and upkeep

Regular cleaning: Regularly clean the interior and exterior of the equipment to remove dust, stains, etc., and maintain the cleanliness of the equipment.

Check components: Regularly check whether all components of the equipment are in good condition, and replace them in a timely manner if there is any damage or wear.

Maintaining the laser: The laser is the core component of the equipment and requires regular maintenance to ensure its stability and lifespan.