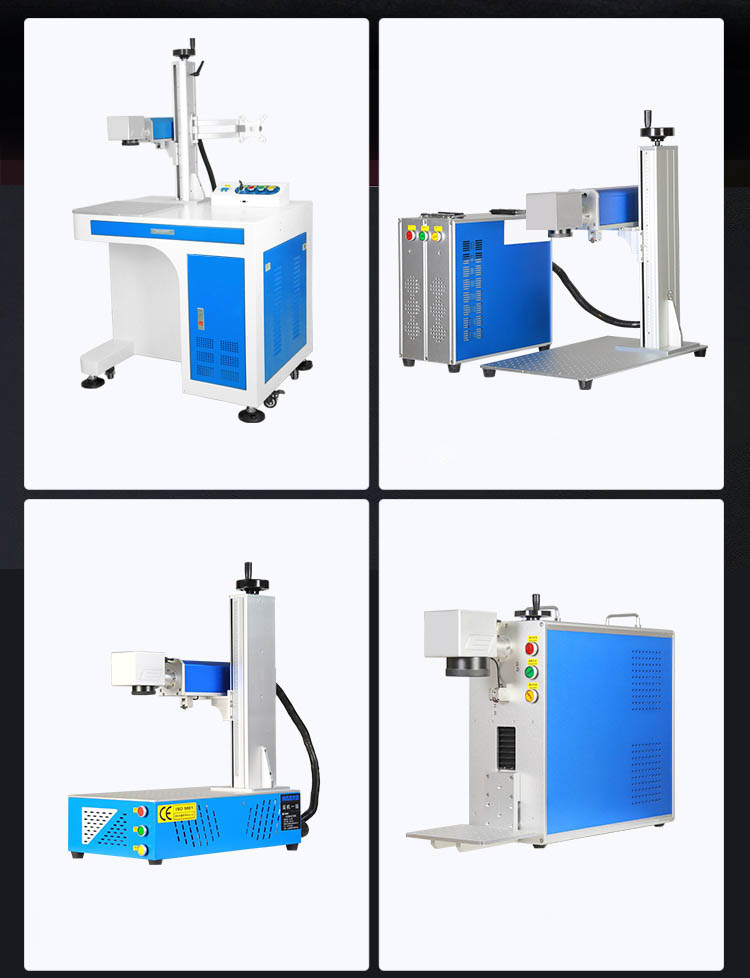

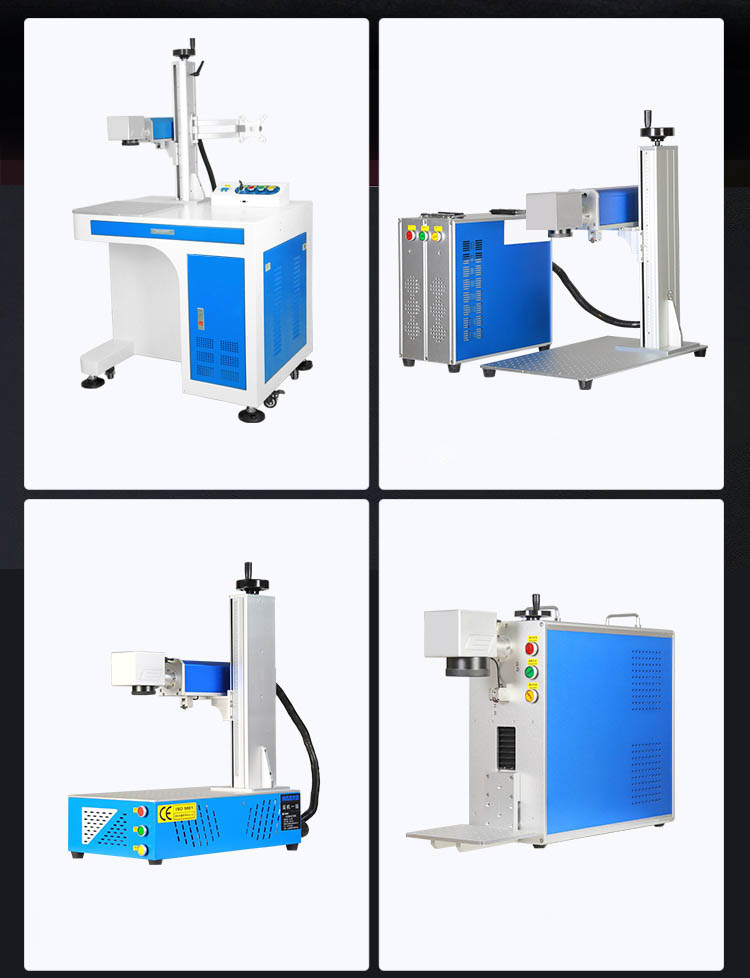

Introduction to Laser Marking Machine Products

1、 Product Overview

Laser marking machines, as indispensable precision equipment in modern industrial fields, are widely used in various industries due to their high efficiency, precision, and environmental protection characteristics. This product adopts advanced laser technology and precision control system, which can achieve high-precision and high-definition marking on various material surfaces. It is an ideal choice to improve product quality and enhance brand image.

2、 Product features

Efficiency: The laser marking machine adopts a high-speed scanning system, which can complete a large number of marking tasks in a short time, greatly improving production efficiency.

Accuracy: The equipment is equipped with a high-precision laser head and an intelligent control system, which can achieve micrometer level marking accuracy, ensuring that every mark is clear and accurate.

Flexibility: Supports marking on various materials, including metals, plastics, glass, ceramics, etc., to meet the needs of different industries.

Environmental friendliness: The laser marking process does not require the use of any chemical reagents, is pollution-free, noise free, and meets modern environmental requirements.

Easy to operate: The device adopts a user-friendly design, with a simple and easy to understand operating interface, which is easy to get started. At the same time, it supports remote control and data transmission, making production management convenient.

3、 Application field

Laser marking machines are widely used in the following fields:

Electronics industry: Used for labeling logos, serial numbers, QR codes, etc. on electronic products such as mobile phones, computers, and tablets.

Automotive industry: used for automotive parts, logos VIN code and other markings.

Jewelry industry: used for marking precious items such as gold, silver jewelry, diamonds, etc.

Medical industry: used for marking medical devices, drug packaging, etc.

Packaging industry: used for marking various packaging materials, labels, etc.

4、 Technical parameters

Laser type: Fiber optic can be selected according to customer needs CO2、 UV and other types.

Laser power: Provide laser sources with different powers based on material and application requirements.

Marking speed: up to XX meters/second, ensuring fast and efficient production.

Marking range: Different sizes of marking areas can be customized according to customer needs.

Repetitive positioning accuracy: ± 0.01mm, ensuring marking accuracy and consistency.