2000W Laser Welding Machine - White

1、 Product Overview

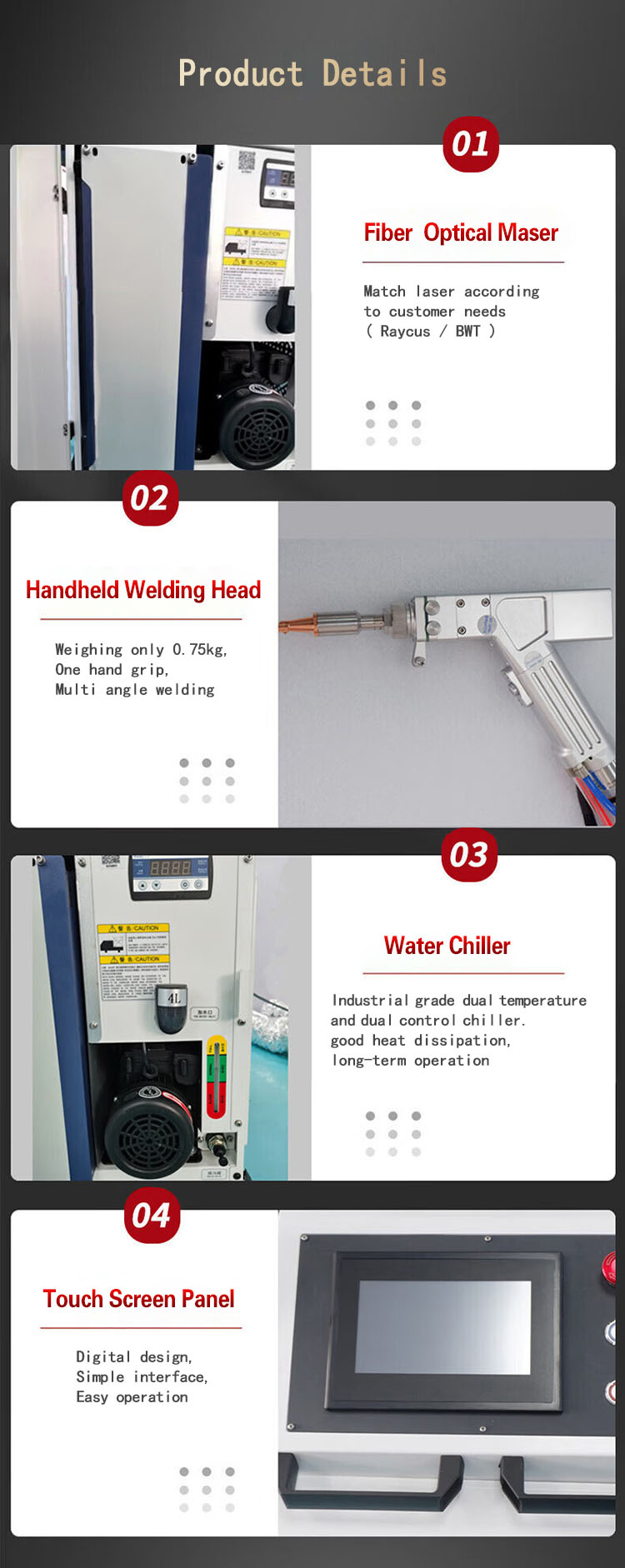

The 2000 watt handheld laser welding machine is a high-performance welding equipment designed specifically for welding metal materials. It combines a new generation of fiber lasers with independently developed welding heads, providing high-precision and high-efficiency welding solutions.

2、 Main Features

High power laser output: Using a 2000w fiber laser, it ensures high energy density and stability during the welding process.

High weld quality: fast welding speed, small heat affected area, small deformation, smooth and beautiful weld seam, no need for post weld treatment or simple treatment to achieve high quality requirements.

Easy to operate: The device has a compact structure, light weight, and is convenient for handheld operation. At the same time, adopting an intuitive operating interface and control system makes the operation simpler and easier to understand.

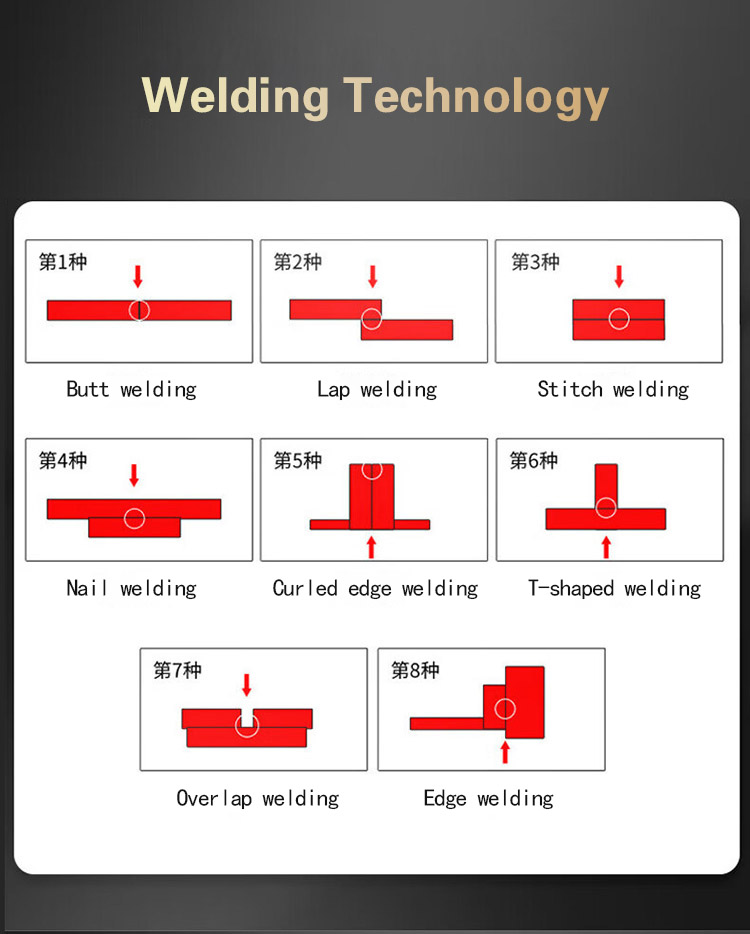

Strong adaptability: It can weld various metal materials, including stainless steel, carbon steel, alloy steel, etc., and is suitable for workpieces of different thicknesses and shapes.

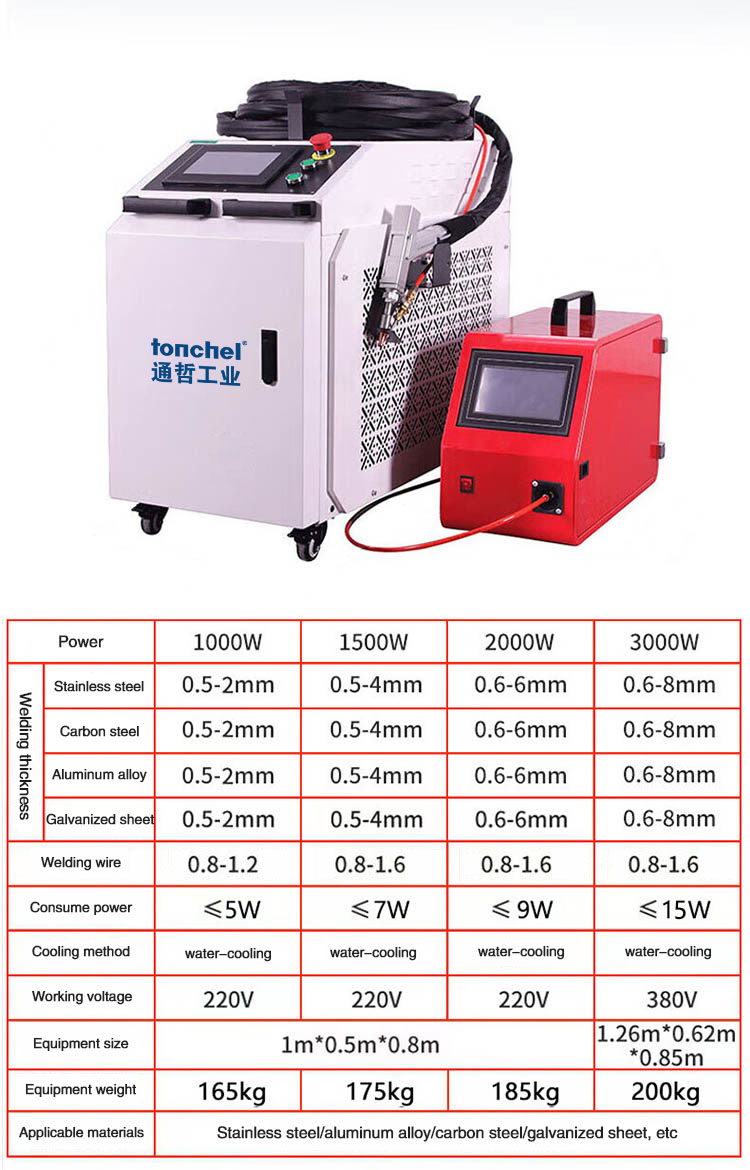

3、 Technical Parameters

Laser power: 2000W;

Laser wavelength: 1070nm;

Operating mode: continuous/modulation;

Laser frequency: 50/60Hz;

Welding speed: 0-190mm/s;

Cooling mode: water cooling;

Spot range: 0.5-5mm;

Working temperature: 0-40 ℃;

Power demand: AC220V

4、 Application Field

The 2000 watt handheld laser welding machine has a wide range of application prospects in fields such as electromechanical equipment, sheet metal, hardware processing, advertising decoration, engineering construction, steel structures, door and window guardrails, household appliances, kitchenware and bathroom, automotive parts, new energy, medical equipment, aerospace, etc. It can meet the welding needs of various complex welds, improve welding quality and efficiency, and reduce production and labor costs.